HERD’s Legacy Products Reimagined – An Inside Look with HERD’s Engineers

Get an exclusive glimpse into the innovative minds behind HERD’s legacy Truck Guards, showcasing the blend of cutting-edge technology and engineering expertise.

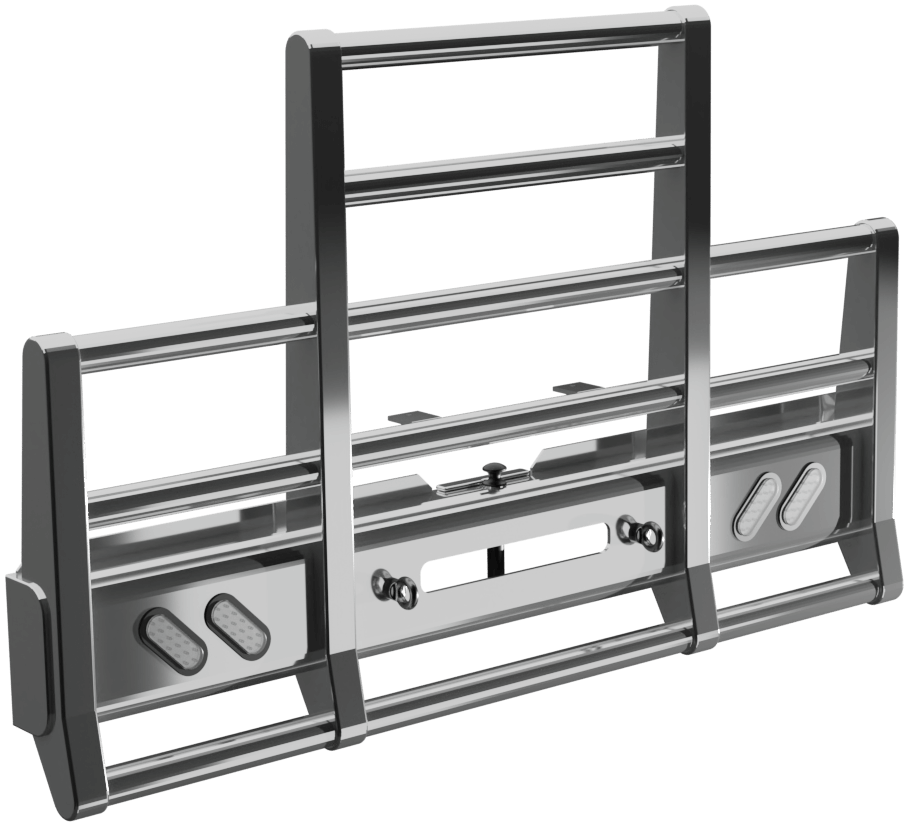

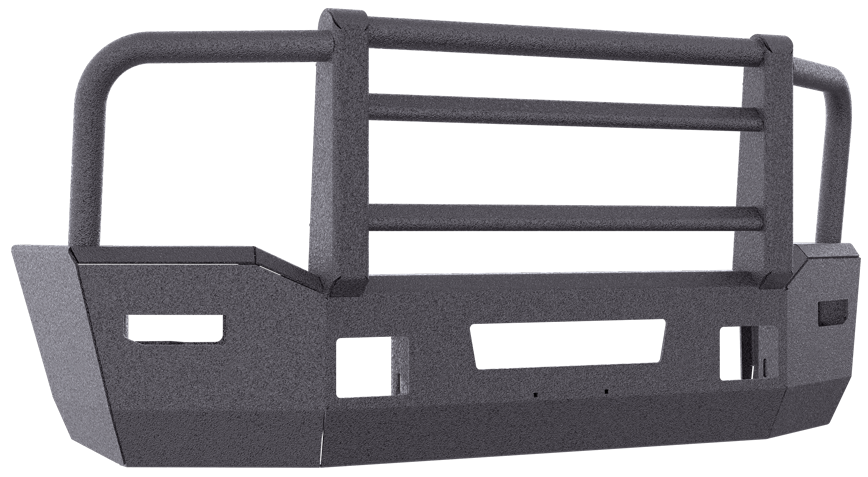

The right equipment does more than just solve a singular problem. It balances functionality, durability, and safety. At HERD, our engineering team is obsessed with achieving the best possible synergy between all of these elements. This philosophy is at the core of our reimagined legacy Truck Guards, which seeks to reimagine the traditional approach to front-end protection.

We recently sat down with Sr. Product Designer Meghdad Saediamiri, to delve into the intricacies of redesigning HERD’s legacy Truck Guards. It was an opportunity to get a first-hand account of the creativity, technical prowess, and sheer dedication that goes into reinventing a product already at the industry’s pinnacle. Meghdad, with his deep passion for engineering and innovation, shared insights that highlight the complexities of design and manufacturing and reflect the spirit of ingenuity that is a hallmark of HERD.

The Essence of Redesign: Lighter, Stronger, Smarter

Can you provide an overview of what inspired the redesign and development?

The redesigned legacy products represent a blend of tradition and technological advancement. We aimed to integrate modern manufacturing methods, like laser welding, which work best with sheet metal. This decision was partly driven by our desire to streamline our supply chain, reducing dependency on externally sourced parts and extrusions.

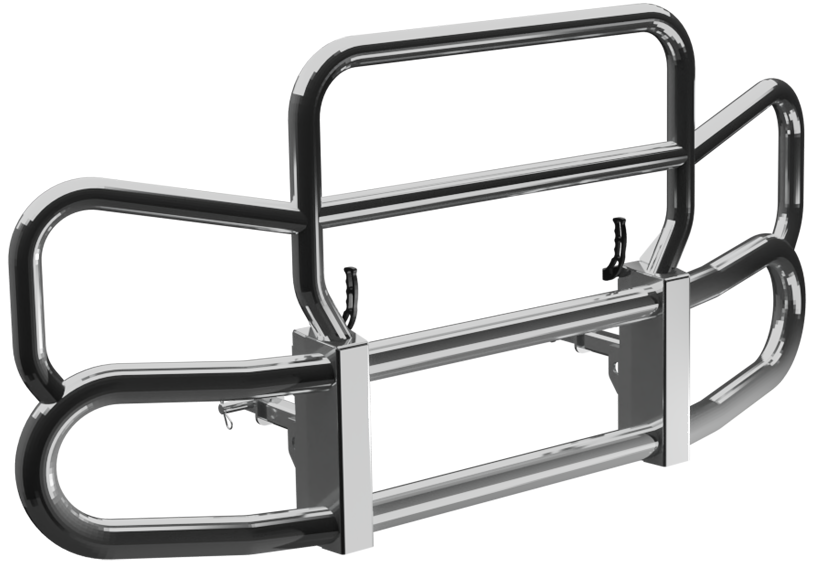

Additionally, we wanted to ensure our Truck Guards were compatible with front-end collision avoidance systems (CAS), which are becoming increasingly crucial for driver safety. The result is a lighter product that surpasses the strength of its predecessor. We’ve also incorporated improvements in the latching and lift-assist mechanisms.

What features or enhancements differentiate the redesigned legacy products from its predecessors and competitors?

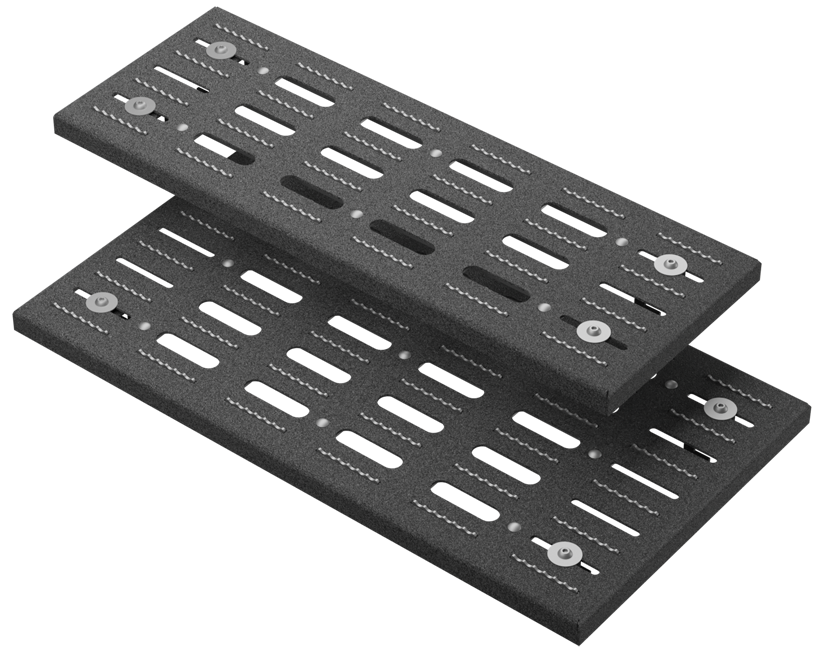

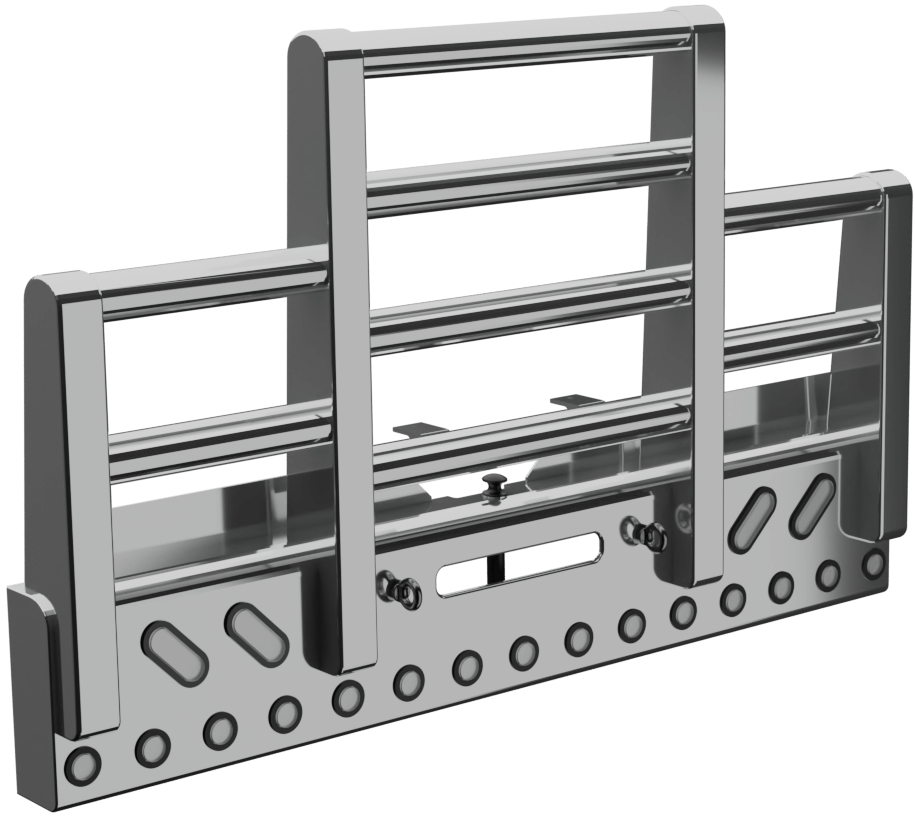

The redesigned legacy guards stand out primarily due to their CAS compatibility. They have a robust, maintenance-free latching system, enhanced with a simple adjustment mechanism when needed. The hinge mechanism and an advanced lift-assist system have been improved for better durability and ease of use. We opted for more bolted components instead of welded ones, providing greater strength and easier replacement if needed. The steel hinge supports have replaced aluminum for added sturdiness, and we’ve added struts for extra rigidity. Also, the mounting system has undergone significant upgrades, including the main bracket and submount.

Can you talk about the materials used in the manufacturing process and their benefits for durability and performance?

We’ve used strong, wear-resistant steel for the latching system, hinges, and towing provisions, ensuring maximum durability and performance. The bumper is made from a strong aluminum alloy known for its resilience and lightweight properties. Additionally, the same alloy and temper of aluminum are used across multiple components to improve the quality of welded joints.

What advancements in technology or manufacturing processes have been incorporated into the new guard’s production?

Laser welding plays a crucial role, allowing for more precise and accurate joints. Robotic sanding and polishing ensure a consistent and high-quality finish. We also adopted bolted connections over welded ones for greater strength and ease of maintenance. Our sheet metal CNC laser cutting and forming capabilities have been critical in achieving the precision required for the new design.

What sort of real-world applications do you see for the redesigned Truck Guards?

HERD Truck Guards are ideal for many drivers, from long-haul to those in more rugged environments. They offer the durability, safety, and reliability required for various applications, whether it’s on highways or off-road conditions.

How do they contribute to reduced maintenance and repair costs for truck owners?

The maintenance and repair costs are significantly lower due to the robust latching system and the shift to more bolted components. The easier replacement of parts and the overall durability of the guard means that truck owners will see a reduction in maintenance frequency and costs.

Can you share insights into the collaboration and expertise of the engineering team behind the new guard’s development?

The engineering team has played a crucial role in redesigning the legacy products. We had initially planned a 16-month project timeline, but due to the accelerated depletion of the existing Texas channels, the team had to bring the completion date to mid-August, pushing themselves to the limit while balancing their regular duties.

Randy played a pivotal role in leading the design of the new Bracket and Mounting System platform, working closely with me. Together, we incorporated features like CAS Radar compatibility, adjustable Impact Plates, and a vastly improved Slam Latch, all while streamlining the design to reduce the number of parts and improve manufacturability. A notable example is the KW16/24 Bracket. The new design is more streamlined and efficient than the legacy versions that require plasma cut notches.

In the final month, the project became a concerted effort from the entire Engineering team. Phuc and Andrew were instrumental in customizing the steel-mounting and aluminum bumper components for the initially released SKUs.

TJ and Manqi developed the fixtures used for the precise manufacturing of key guard components. Phil provided vital support throughout the project, assisting in creating and reviewing all engineering drawings. With Phil’s support, Isaiah conducted critical physical impact testing of the newly formed Texas channel.

The production team also played a crucial role, working hand in hand with the engineering team to skillfully build various design versions and ensure quick turnaround times.

The entire team’s dedication and hard work were instrumental in making this project a success, and everyone involved should be incredibly proud of their accomplishments!

Where Legacy Meets Evolution

The decision to reimagine HERD’s Truck Guards is not about changing the essence of what made these products great; it’s about refining them for the future. Every product we craft at HERD isn’t just a piece of equipment; it’s a testament to our promise of delivering excellence in every weld, bolt, and design decision.

At HERD, we don’t just follow the best practices; we create them.