We have customization

down to a science.

Quality Materials

We build our products with state-of-the-art materials that keep trucks safe without adding extra weight, allowing drivers to stay safe and reach their full potential.

Innovative Designs

Our team of experts meticulously calculate each design for function in order to create the most innovative and distinct products on the market.

Advanced Engineering

Our engineers use cutting edge technology to tailor each product to meet your specific needs.

Solid protection and uncompromising safety to keep your truck and your bottom line looking good.

Warranty

HERD leans on advanced engineering to create products that outperform our competitors and create new paths toward innovation. We believe in our work and stand by each product with a secure warranty that will exceed your expectations.

Best-in-class products

For every part of your truck

Select a product line

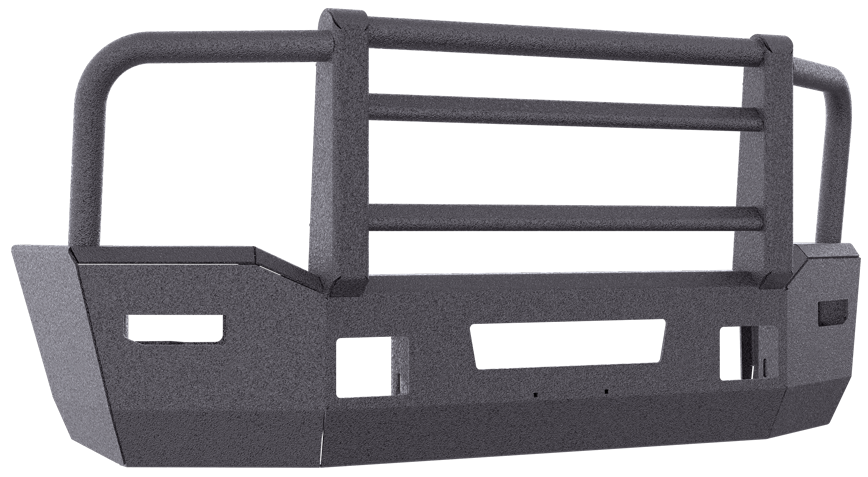

Stealth Defender

Stealth Defender

Shop Truck Guards

Weighing less than 300 lbs, the Stealth Defender offers a strong defense against collisions, debris, and other elements, and the all-new “satin” finish means you won’t have to sacrifice style to stay safe.

Aero

Aero

Shop Truck Guards

HERD’s best-selling Truck Guard provides premium defense without sacrificing weight.

Defender

Defender

Shop Truck Guards

Best-in-class materials and premium manufacturing protect your rig from costly damage and unnecessary repairs.

Texas

Texas

Shop Truck Guards

Signature southern style for trucks that go off the beaten path.

Big Tex

Big Tex

Shop Truck Guards

Take pride in your rig by outfitting it with a unique style and protection the size of Texas.

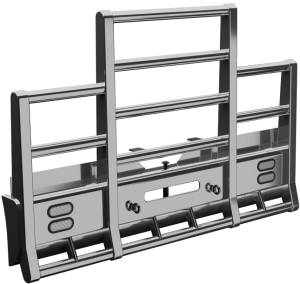

Super Road Train

Super Road Train

Shop Truck Guards

Defend your truck against moose, deer, or any other obstacle you might encounter with one of the biggest and toughest guards on the market today.

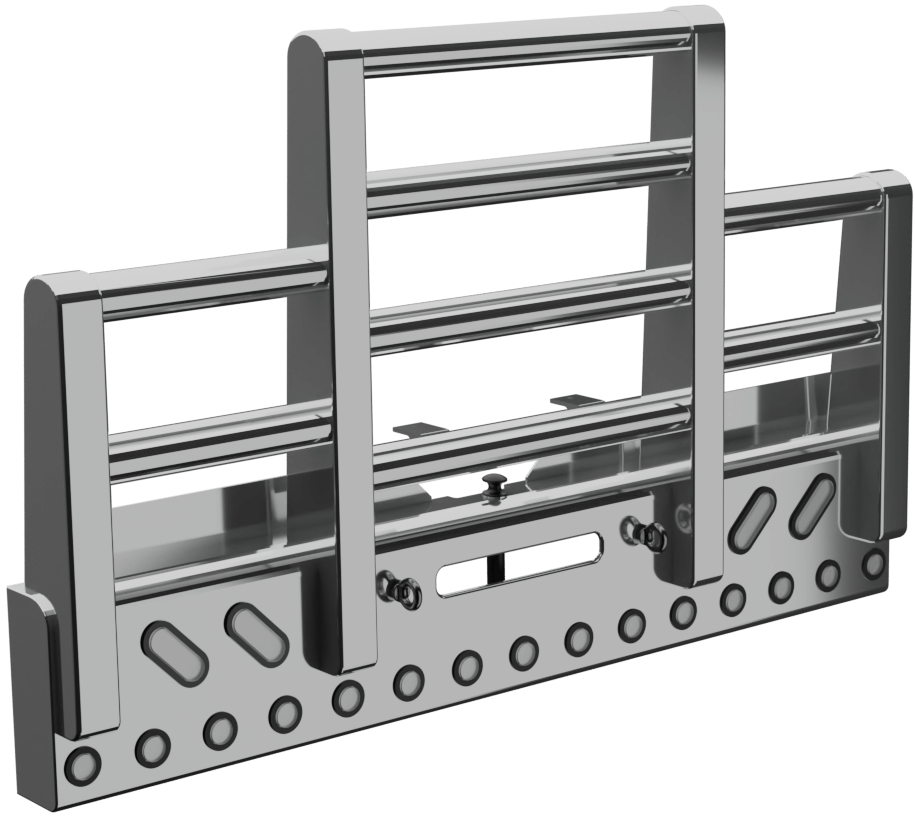

Road Train

Road Train

Shop Truck Guards

Strong enough for the legendary Australian Road Train, but adapted for the North American Market.

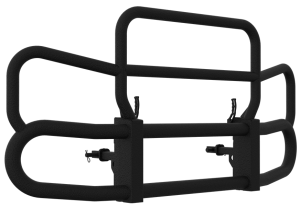

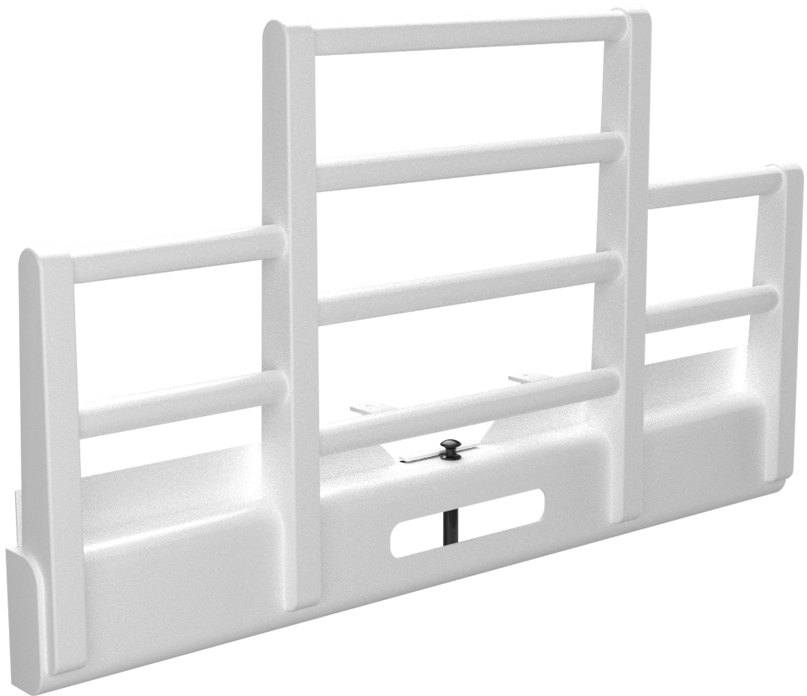

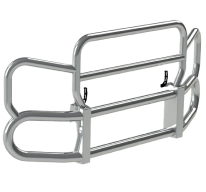

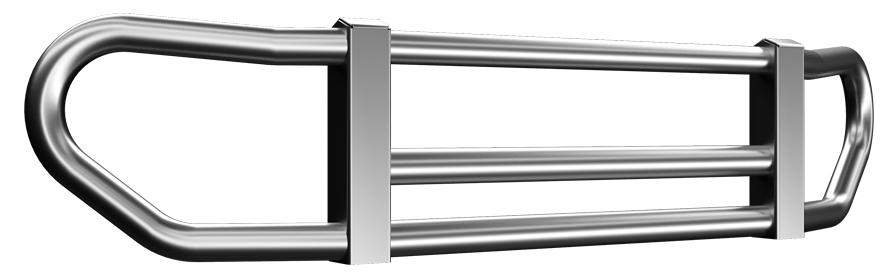

Grille Guard 100

Grille Guard 100

Shop Grille Guards

Designed in conversation with fleet managers and manufactured with the highest quality materials, allowing you to stay on the road and accomplish your goals.

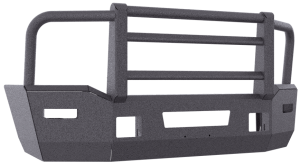

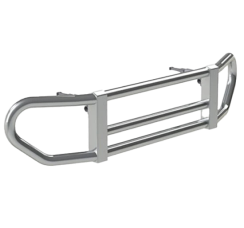

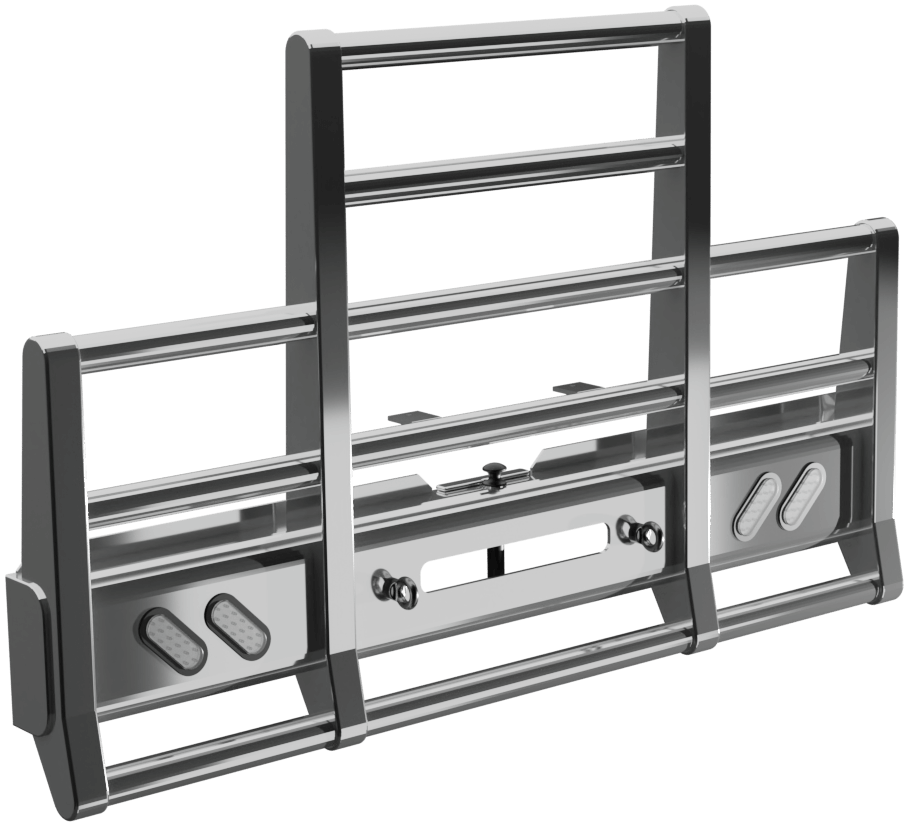

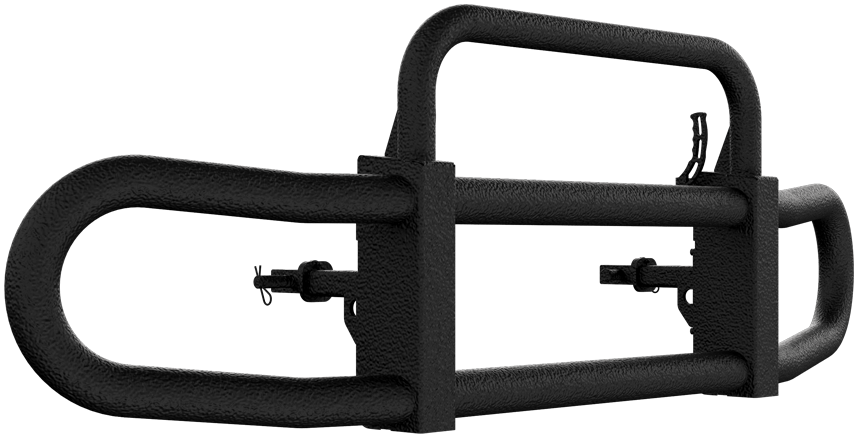

Grille Guard 200

Grille Guard 200

Shop Grille Guards

Protect your asset from brush, deer, and unexpected collisions with a unique style that enhances the look of your rig.

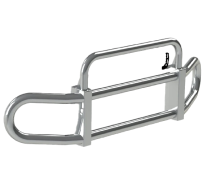

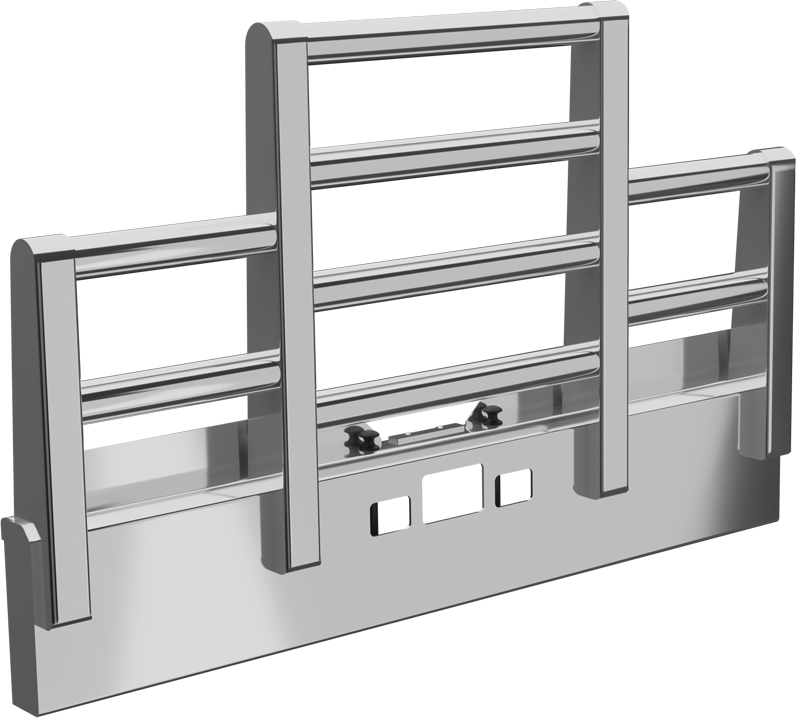

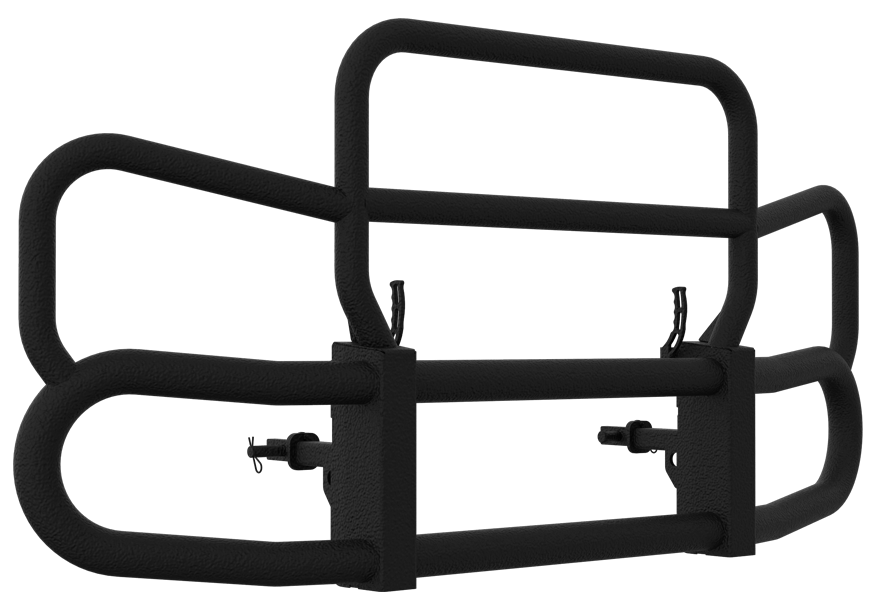

Grille Guard 300

Grille Guard 300

Shop Grille Guards

A distinct look that’s ready to meet the demands of the road providing premium defense against costly repairs and downtime.

Cabinet Rack

Cabinet Rack

Shop Cab Racks

The best utility storage alternative on the market, its look compliments your truck while providing the ability to customize each cabinet to your needs.

Chain Hanger Rack

Chain Hanger Rack

Shop Cab Racks

Engineered to last and designed to impress, providing you with unparalleled storage options in chain hanger and flat deck chain hanger styles.

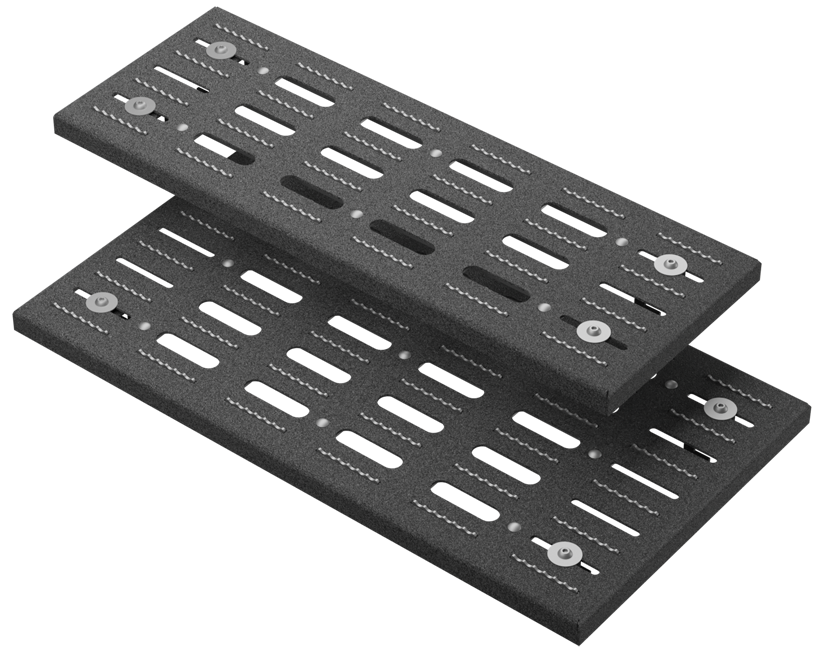

Deck Plates

Deck Plates

Shop Accessories

Increased protection and quality tread, allowing you to walk on your frame safely.

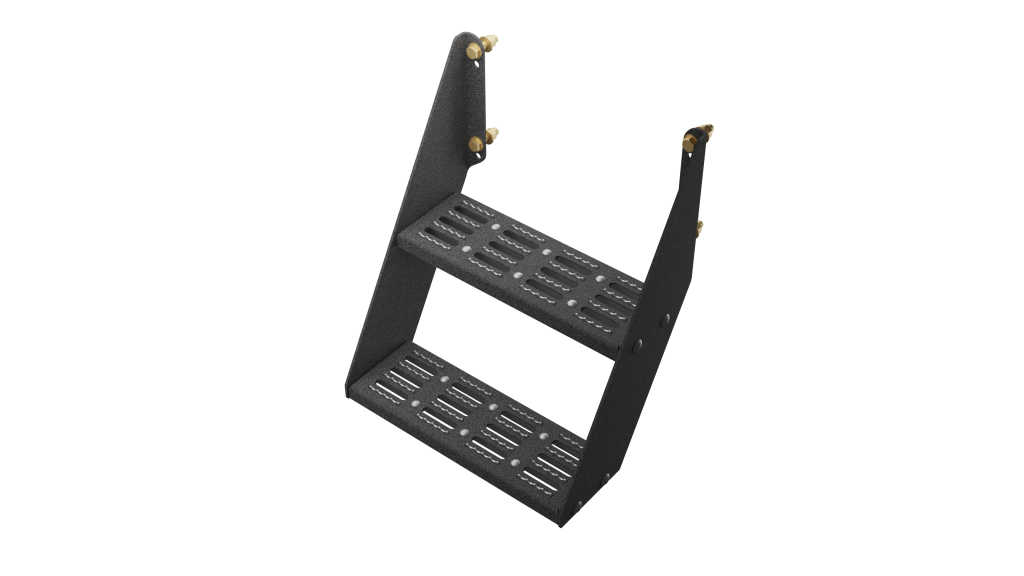

Steps

Steps

Shop Accessories

Enhance your truck’s look and get easy access to the cab of your truck.

Toolboxes

Toolboxes

Shop Accessories

Truck Guard Bolt-Ons

Truck Guard Bolt-Ons

Shop Accessories

Grille Guard Bolt-Ons

Grille Guard Bolt-Ons

Shop Accessories

Cab Guard Bolt-Ons

Cab Guard Bolt-Ons

Shop Accessories

Previous

Next

HERD grille guards have saved us about $30,000 in the last week alone in four different accidents.

Brandi Borrowman

Glitner, Inc.