Our Promise

sets us apart

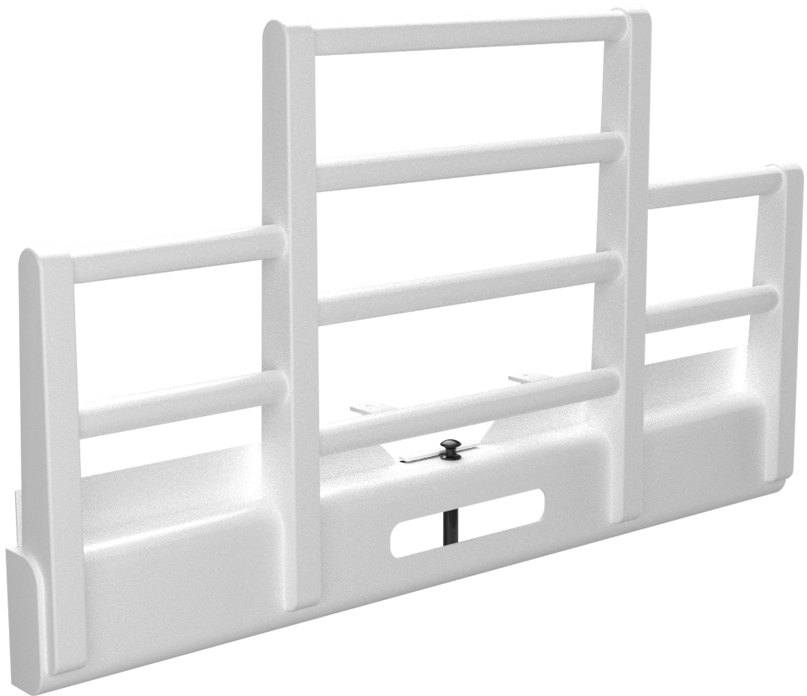

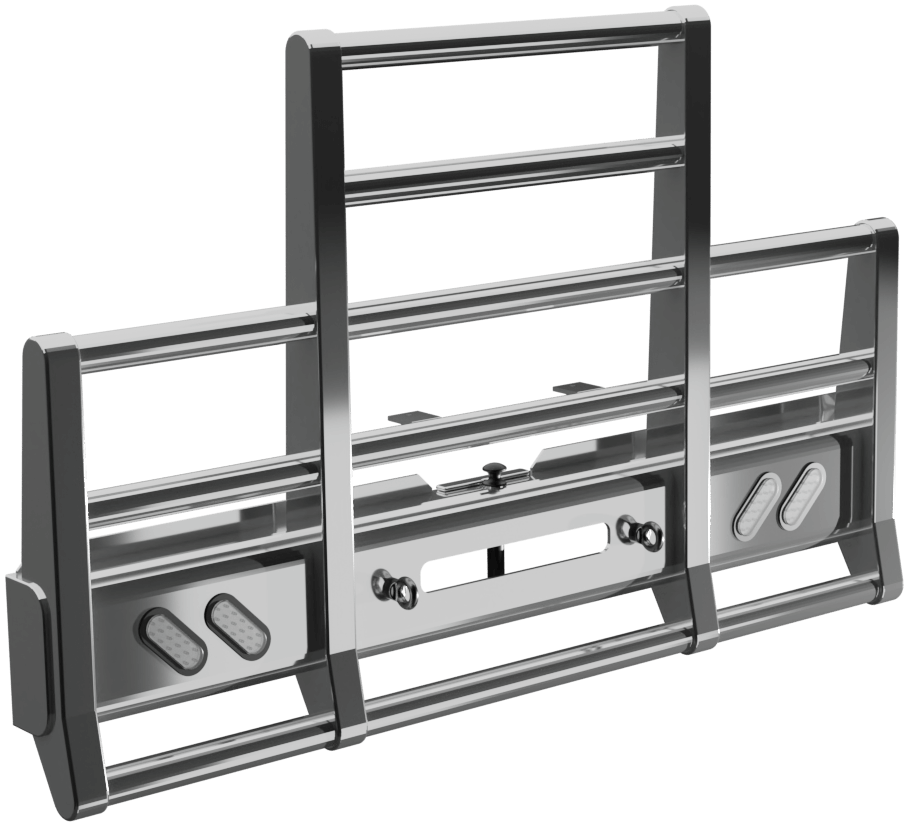

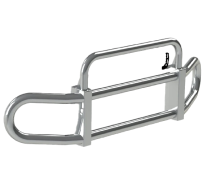

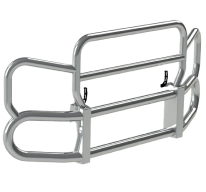

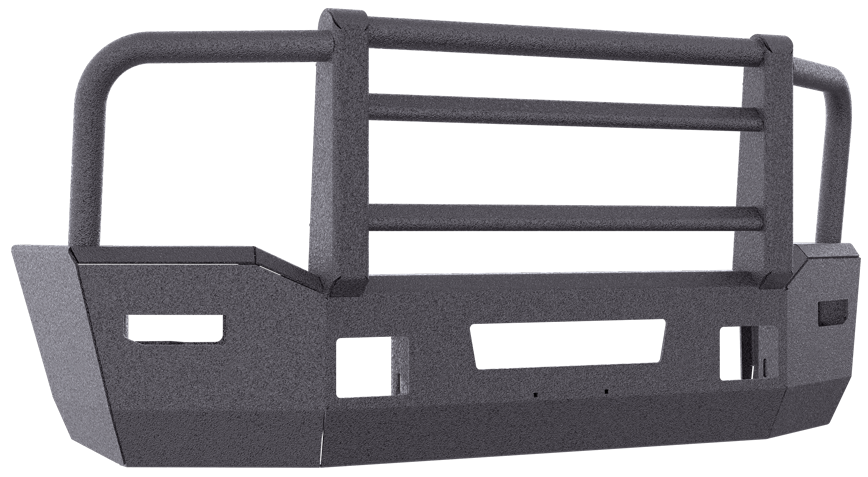

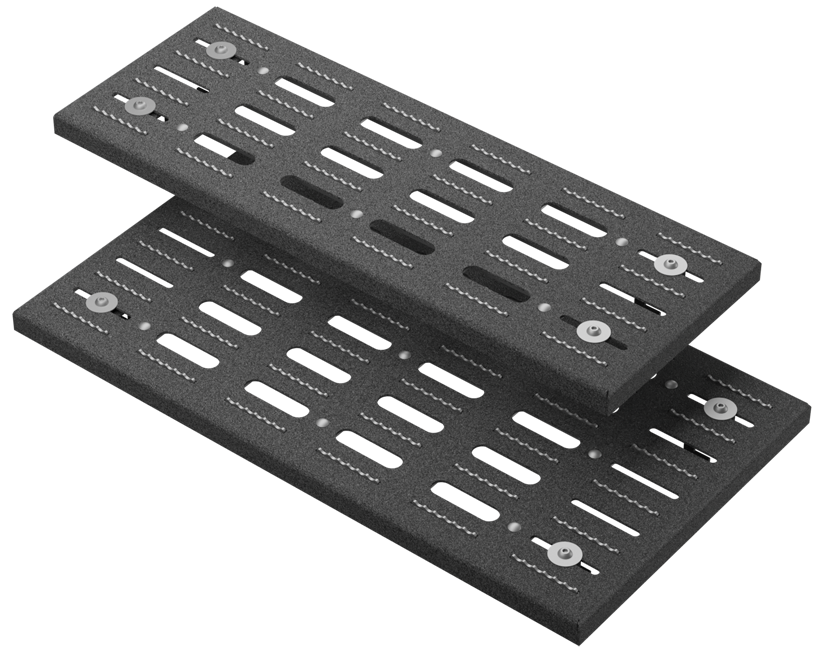

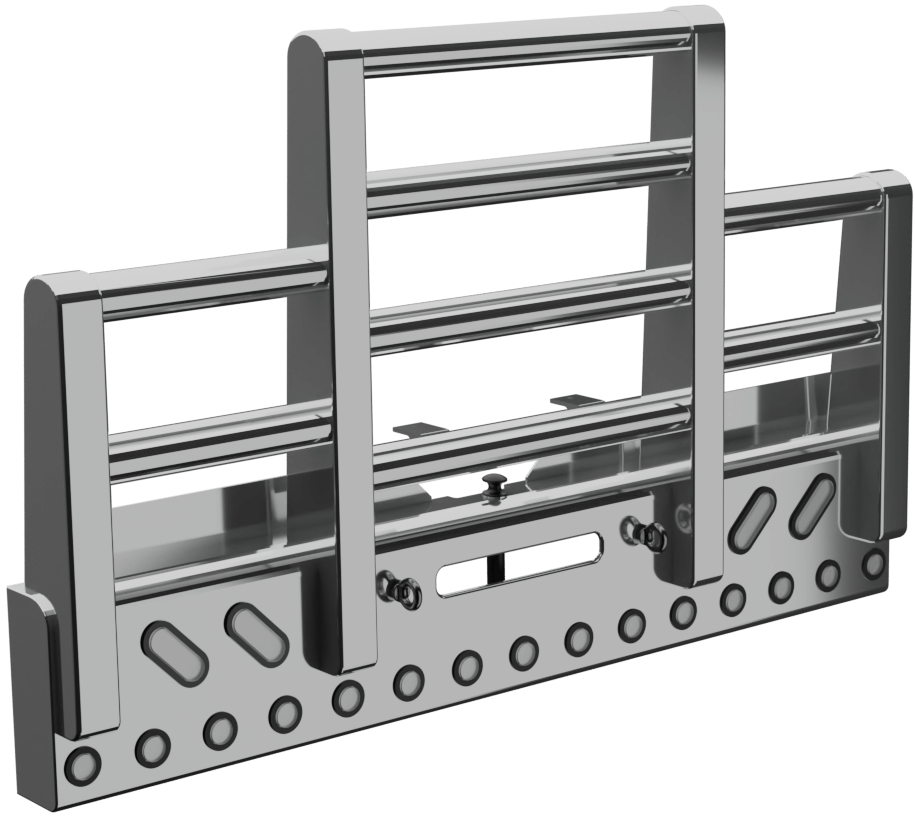

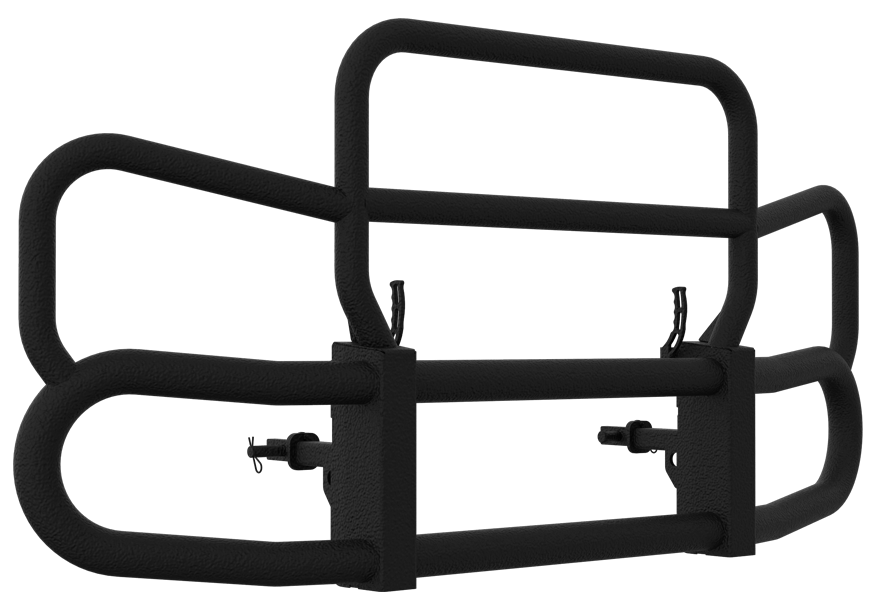

HERD is one of North America’s leading vehicle guard companies. Founded in 2003, we’re the only manufacturer to market four distinct product lines, including Bumper Guards, partial and full Grille Guards, Pickup Truck Guards and Truck Guards. Our customer-centric approach combined with our results-oriented culture ensures that whatever product you install, both your vehicle and bottom line will be protected.