Midwest and prairie commercial trucking faces unique regional challenges. Freeze-thaw cycles destroy inferior equipment, prairie winds kick up debris, and wildlife populations create constant collision risks. From North Dakota oilfields to Texas agriculture, Minnesota winters to Montana mountains, protection equipment must perform across extreme conditions.

Prairie truck guards built for regional demands become essential. HERD engineers commercial truck protection Midwest operations require. Our winter truck protection handles temperatures from 40 below to over 100 degrees. For agricultural truck guards or regional fleet protection, HERD delivers equipment tested in Midwest conditions.

The Midwest and prairie regions span diverse geography but share common challenges. Temperature extremes, wildlife populations, agricultural operations, and energy extraction all create front-end protection needs that generic equipment can’t address effectively.

Understanding Midwest and Prairie Conditions

The Midwest and prairie regions create unique challenges that demand specialized equipment approaches. Temperature swings from winter cold to summer heat stress materials through constant expansion and contraction cycles. Open prairie means high winds carrying debris across highways. Rural routes connect remote facilities with limited service access, making breakdowns particularly problematic.

Spring brings severe weather, including thunderstorms and flooding. Summer heat stresses cooling systems while increasing agricultural shipping demand. The fall harvest season creates peak operational periods when equipment downtime has maximum financial impact. Winter combines extreme cold with ice, snow, and corrosion from road treatments.

Regional requirements include freeze-thaw resistance, temperature performance across extreme ranges, wind-debris defense, wildlife protection from deer through moose, and corrosion resistance from both road salt and agricultural chemicals.

Semi truck grille guards and truck guards prevent damage during these peak periods when operations can least afford downtime.

Winter Weather Protection Demands

Midwest winters test equipment through freeze-thaw cycles, road salt exposure, and extreme cold that challenge materials and mechanisms. Freeze-thaw cycles create expansion and contraction that crack inferior materials over time. Road salt and chemical deicers used extensively across the region accelerate corrosion in standard steel components.

HERD uses 304 stainless steel in grille guards specifically because this grade resists corrosion from deicers while maintaining structural integrity through years of winter exposure. The material doesn’t rust like carbon steel, providing long-term durability despite aggressive winter road treatments.

Aluminum truck guards provide different advantages for winter conditions. Aluminum doesn’t rust at all and handles freeze-thaw cycles without cracking or material degradation. The material maintains strength across the full temperature range from summer heat to winter cold. Welds remain sound through thermal cycling.

The Grip Latch and Slam Latch mechanisms operate reliably in extreme cold without cables freezing or mechanisms seizing. When doing pre-trip inspections in freezing temperatures, these systems provide engine access without the failures common in cable-operated latches.

Prairie Route Challenges

Open prairie creates strong winds that kick up rocks, agricultural residue, and road debris. Strong winds common across North Dakota, South Dakota, Nebraska, and Kansas accelerate debris to speeds that damage unprotected front ends. At highway speeds, this material becomes projectiles capable of cracking lights and damaging radiator fins.

Agricultural routes add grain dust, fertilizer exposure, and rough access roads to remote facilities. Spring mud season on rural routes tests equipment durability. Harvest season brings heavy traffic on county roads not designed for high commercial truck volumes. All these factors combine to create wear patterns unique to prairie agricultural operations.

HERD guards protect against these prairie-specific hazards. The structural design handles debris impacts, while materials resist agricultural chemical exposure despite constant dust, mud, and field residue exposure common throughout growing and harvest seasons.

Wildlife Collision Risks Across the Region

Midwest and prairie wildlife create serious collision risks across all operational areas. White-tailed deer populate the entire region from Wisconsin to Texas. Mule deer inhabit western prairie states. Elk herds move across Montana, Wyoming, and parts of the Dakotas. Moose inhabit northern Minnesota, North Dakota, and Canadian prairie regions.

A white-tailed buck weighs 200 pounds. Elk exceed 700 pounds. Bull moose reach 1,200 pounds or more. At highway speeds, collisions with these animals generate catastrophic forces that destroy unprotected radiators, lights, sensors, and cooling systems. Even near misses can cause significant damage when debris flies at impact.

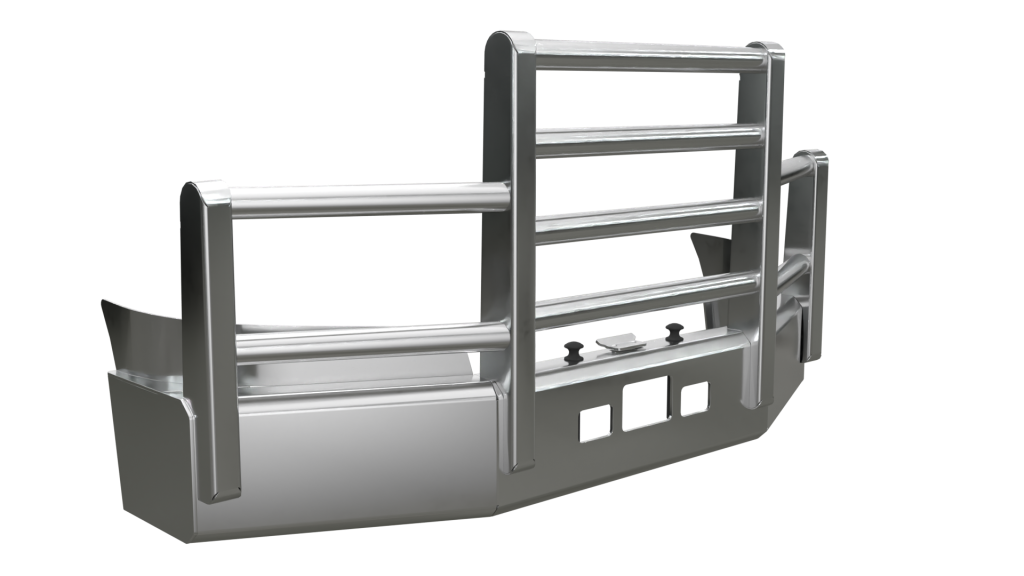

HERD guards absorb and distribute collision forces across their structure rather than allowing damage to concentrate on vulnerable components. The HERD Grille Guard 300 uses 304 stainless steel with 3.5-inch lower and 2.75-inch top tubes engineered specifically to handle serious impacts.

For moose or elk territory, heavy-duty aluminum truck guards provide maximum coverage. The Super Road Train truck guard offers premium protection with four-inch tubes and a 16-inch Aero-style bumper built for demanding conditions where large animal encounters occur regularly.

Agricultural and Oilfield Applications

Midwest agriculture and prairie energy extraction depend on reliable trucking across challenging conditions. Grain moves from fields to elevators across multiple states. Livestock transport connects ranches to feedlots and processing facilities. Oilfield operations in North Dakota, Montana, and Texas require equipment transport on rough access roads to remote drilling sites.

These applications create specific protection needs that generic equipment can’t address. Agricultural hauling involves rural routes where deer crossings are constant and seasonal variations affect operations significantly. Oilfield work means unmaintained access roads with rocks, debris, and harsh conditions that accelerate wear. Both operations run critical time windows where equipment downtime creates a major financial impact.

The HERD Grille Guard 200 provides strong defense for agricultural operations, managing weight considerations while protecting vulnerable components. The Defender aluminum truck guard combines aluminum construction with Impact Plates specifically for oilfield operations needing maximum protection on rough roads without an excessive weight penalty.

Guards are available in polished, satin, or black powder coat finishes to match fleet appearance standards. Free freight on five or more units makes fleet-wide installation more economical.

Long-Haul Interstate Protection

Major interstate corridors like I-90, I-80, and I-35 cross the region, carrying coast-to-coast freight. Interstate speeds increase collision forces. Road debris and wildlife crossings create risks. Long distances between service facilities mean breakdowns cause significant delays.

The HERD Texas truck guard features an 18-inch bumper providing substantial interstate protection. All truck guards include Slam Latch systems and 3-year warranties.

Choosing Regional-Appropriate Protection

Selecting protection means matching coverage to exposure. For agricultural operations on rural routes, grille guards offer excellent protection while managing weight. For mixed operations, including oilfield work or high-risk wildlife areas, truck guards provide comprehensive coverage.

Regional dealers understand local conditions and can recommend appropriate protection levels. Warranty coverage includes 3-year guard warranties and 5-year Grip Latch warranties backed by the dealer network.

Protect Your Midwest Fleet Today

Midwest and prairie operations demand protection built for regional challenges. From freeze-thaw cycles to wildlife collisions, HERD guards deliver proven performance across all conditions.

Whether running grain operations, servicing oilfields, or hauling interstate freight, we have solutions for your requirements. Every HERD product includes industry-leading warranties.

Ready to protect your investment? Contact HERD to connect with regional dealers who understand Midwest operations. Consult about your routes, seasonal challenges, and wildlife exposure.

Frequently Asked Questions

What makes HERD protection suitable for Midwest freeze-thaw conditions?

HERD uses 304 stainless steel in grille guards and aluminum in truck guards, both engineered for freeze-thaw cycling. Stainless steel resists road salt corrosion while aluminum handles expansion and contraction without cracking. Both materials perform across the full Midwest temperature range, from extreme cold to summer heat.

How do guards protect against prairie wildlife like moose and elk?

HERD guards absorb and distribute collision forces from large animals. The Super Road Train with four-inch tubes provides maximum protection for moose and elk encounters. Guards distribute forces across the structure while protecting radiators, lights, and cooling systems from damage.

Can guards work for both agricultural and oilfield operations?

Yes, HERD guards perform across different applications. Many Midwest fleets run mixed operations. Guards protect equally on rural agricultural routes and rough oilfield access roads. Regional dealers specify appropriate protection levels based on operational focus.

What protection works best for long-haul interstate routes?

Truck guards provide comprehensive coverage for interstate operations. The Defender and Texas guards offer substantial protection while maintaining a professional appearance. Construction resists road salt corrosion and handles debris at highway speeds.

How do guards handle regional seasonal variations?

HERD guards perform across the Midwest seasons. Materials resist winter road treatments and spring moisture, handle summer heat, and withstand fall harvest dust. Grip Latch and Slam Latch mechanisms operate reliably in cold weather, with finishes maintaining appearance year-round.