Fleet managers making truck guard materials comparison decisions need to understand how different materials perform in commercial trucking. HERD manufactures protection equipment using 304 stainless steel for grille guards and aluminum for truck guards. Each material suits different protection needs and operational requirements.

HERD has selected these materials based on their performance in real-world conditions. The choice between steel grille guards and aluminum truck guards depends on your fleet’s protection needs and operational environment.

HERD’s Material Selection Approach

HERD manufactures two main categories of protection equipment using materials optimized for each application.

HERD grille guards use 304 stainless steel construction, providing corrosion resistance and structural strength. The HERD Grille Guard 300 features 3″ round tubes engineered for maximum strength, with tapered box uprights, a Grip Latch system, and CAS compatibility. The HERD Grille Guard 200 provides 3″ round tubes with tapered box uprights for solid commercial defense.

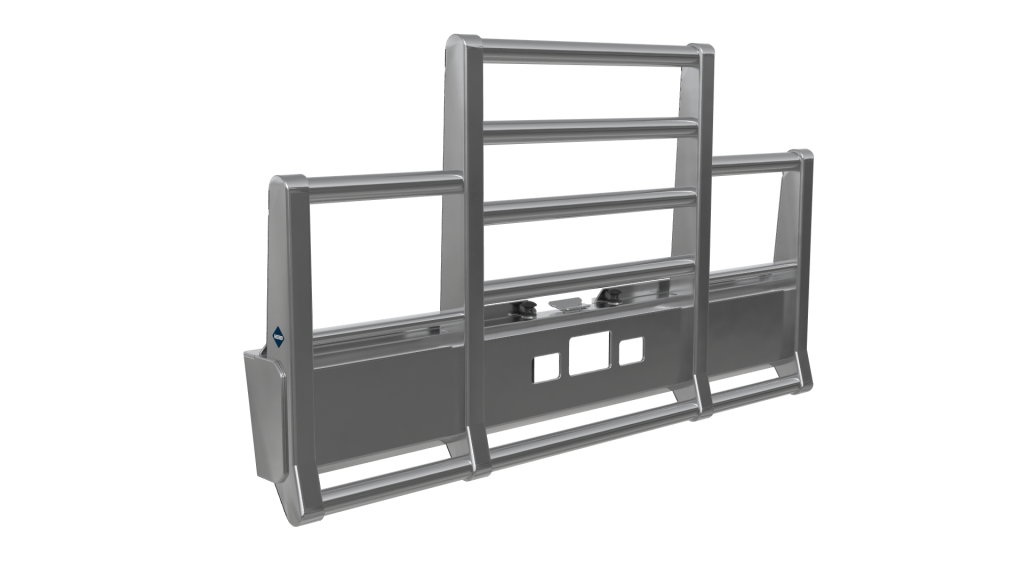

HERD truck guards use aluminum construction. The Defender features aluminum with Impact Plates, the Texas truck guard includes an 18-inch formed aluminum bumper, and the Super Road Train uses an aluminum 16-inch Aero-style bumper. These integrate directly with the truck frame structure for extensive coverage.

Understanding Stainless Steel in Grille Guards

HERD’s 304 stainless steel construction for grille guards provides corrosion resistance from road salt, chemical deicers, and environmental exposure. The material maintains structural integrity through years of service in harsh conditions, including winter road treatments and coastal salt air exposure.

Guards come in three finishes:

- Polished stainless steel

- Satin finish

- Black powder coat

All finishes maintain the underlying corrosion resistance. The stainless steel construction handles forces from wildlife collisions and debris strikes, protecting radiators, condensers, lights, and sensors.

Understanding Aluminum in Truck Guards

Aluminum doesn’t rust, providing natural corrosion resistance in various operating environments. The permanent finishes maintain appearance through years of service without peeling or fading.

The Defender uses aluminum with Impact Plates at around 320 pounds. The Texas guard features an 18-inch aluminum bumper at 380 pounds. The Super Road Train at 510 pounds uses aluminum with four-inch oversized tubes. These larger guards integrate with the frame structure for extensive coverage while managing weight.

Aluminum maintains structural integrity across temperature extremes from below-zero winter to summer heat exceeding 100 degrees, performing consistently for trucks operating across diverse regions and seasons.

Warranty Coverage and Material Durability

HERD’s warranty structure reflects confidence in both materials:

- Grille guards: 3-year warranty on structure, 5-year warranty on Grip Latch

- Truck guards: 3-year warranty on materials and workmanship

The 5-year warranty on the Grip Latch mechanism indicates expected durability through hundreds of thousands of miles of operation.

Maintenance Requirements for Different Materials

Both materials require minimal maintenance. Stainless steel and aluminum guards maintain appearance through standard truck washing with no special products required. Corrosion resistance is inherent to the materials, not dependent on coatings.

Periodic inspection of mounting hardware and post-impact checks apply to both. The Slam Latch and Grip Latch mechanisms operate for years without maintenance beyond basic cleaning.

Application Considerations for Fleet Managers

When selecting protection equipment, consider how different guard types match operational requirements.

Stainless steel grille guards suit highway operations with standard wildlife exposure, mixed fleets requiring consistent protection, and operations wanting guards that mount without frame integration.

Aluminum truck guards suit operations requiring maximum coverage, integration with frame structure, challenging conditions, or remote areas, and fleets prioritizing comprehensive protection.

The mounting approach and coverage area differ between these options, helping fleet managers match protection to their specific needs.

Working with HERD Dealers for Material Selection

Authorized HERD dealers understand how different guards match operational requirements. They can discuss protection levels, truck model integration, and installation requirements.

HERD offers free freight on orders of five or more grille guards with matching SKUs.

Making Informed Material Decisions

Consider your operating environment, geographic range, and collision history when choosing between guard types. Operations with frequent wildlife encounters might prioritize aluminum truck guards’ extensive coverage. Less extreme exposure might suit stainless steel grille guards.

Protecting Your Fleet Investment

Understanding how HERD uses stainless steel in grille guards and aluminum in truck guards helps fleet managers make informed decisions. Both materials perform in real-world commercial conditions.

Ready to protect your fleet? Contact HERD to connect with authorized dealers who can discuss which protection equipment matches your operational requirements.

Frequently Asked Questions

What’s the difference between stainless steel grille guards and aluminum truck guards?

Stainless steel grille guards mount to tow receivers and provide focused protection for radiators, lights, and sensors. They work well for highway operations with standard wildlife exposure. Aluminum truck guards integrate with the truck frame structure and provide more extensive front-end coverage with larger bumpers and substantial construction. They’re designed for operations requiring maximum protection. The material choice relates to the guard type and protection level—grille guards use stainless steel, and truck guards use aluminum. Your operational requirements determine which type suits your fleet.

How do both materials handle corrosion in different environments?

Both 304 stainless steel and aluminum provide corrosion resistance in commercial trucking environments. Stainless steel grille guards resist corrosion from road salt, chemical deicers, and environmental exposure without rusting. Aluminum truck guards don’t rust and maintain structural integrity through exposure to humidity, chemicals, and varying weather conditions. Both materials perform across diverse operating environments, including coastal regions, winter road treatment areas, and varying climate zones. The permanent finishes on both materials maintain appearance through standard truck washing without requiring special treatments.

Do different materials affect maintenance requirements?

Both stainless steel grille guards and aluminum truck guards require minimal maintenance. Neither material needs special cleaning products or protective treatments—standard truck washing procedures work for both. The corrosion resistance is inherent to the materials, not dependent on coatings. Periodic inspection of mounting hardware and post-impact checks apply to both guard types, regardless of material. The Slam Latch and Grip Latch mechanisms on both guard types operate for years without maintenance beyond basic cleaning. Material choice doesn’t significantly change the minimal maintenance requirements HERD guards demand.

How does material selection relate to warranty coverage?

HERD provides warranty coverage based on guard type rather than material. Grille guards (stainless steel construction) include a 3-year warranty on the guard structure and a 5-year warranty on the Grip Latch mechanism. Truck guards (aluminum construction) carry a 3-year warranty covering materials and workmanship. These warranty periods reflect HERD’s confidence in the durability of both material selections through extended commercial service. Warranty service is handled through the authorized dealer network, providing local support regardless of which guard type and material your fleet uses.

Should fleet decisions prioritize material type or protection level?

Fleet decisions should prioritize operational requirements over material type specifically. The material HERD uses relates to the guard type and protection level you select. Consider your typical routes, wildlife exposure, and whether you need focused front-end protection or comprehensive coverage. Stainless steel grille guards and aluminum truck guards both perform in commercial trucking conditions—the choice between them depends on the protection level needed rather than material preference. Work with HERD dealers who can discuss which guard type matches your operational requirements, and the material selection follows from that decision.