February 20, 2023

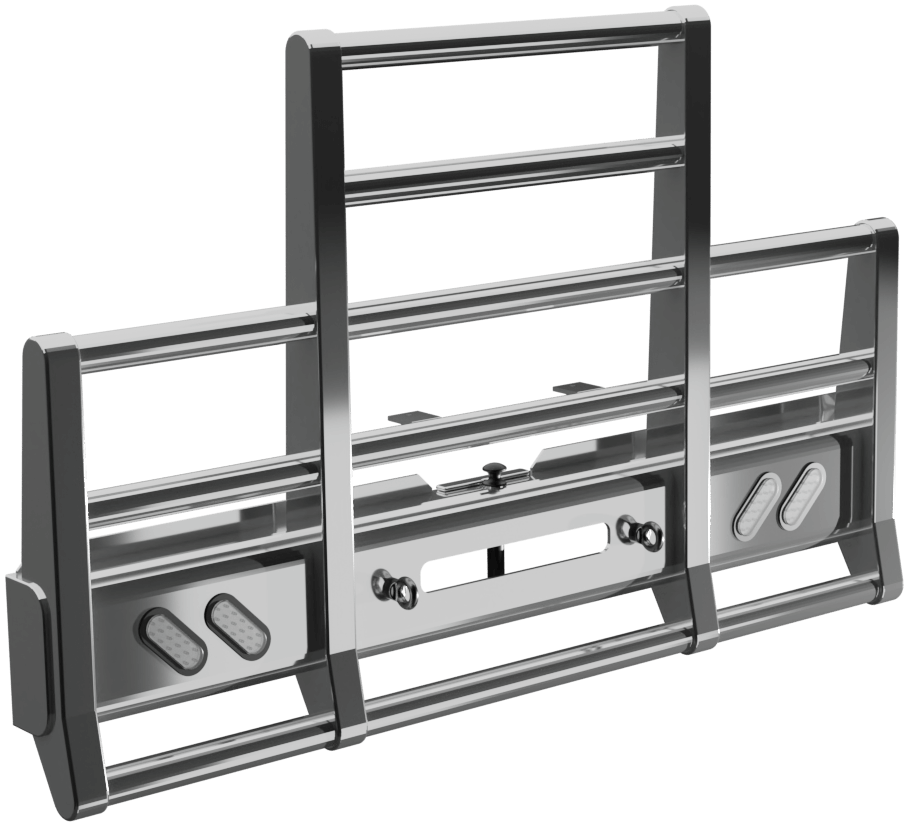

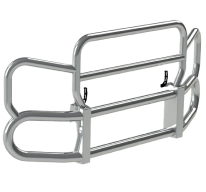

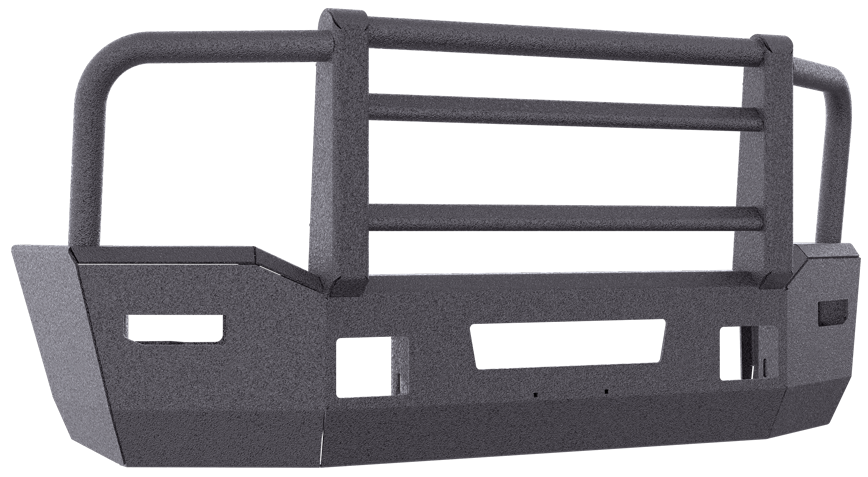

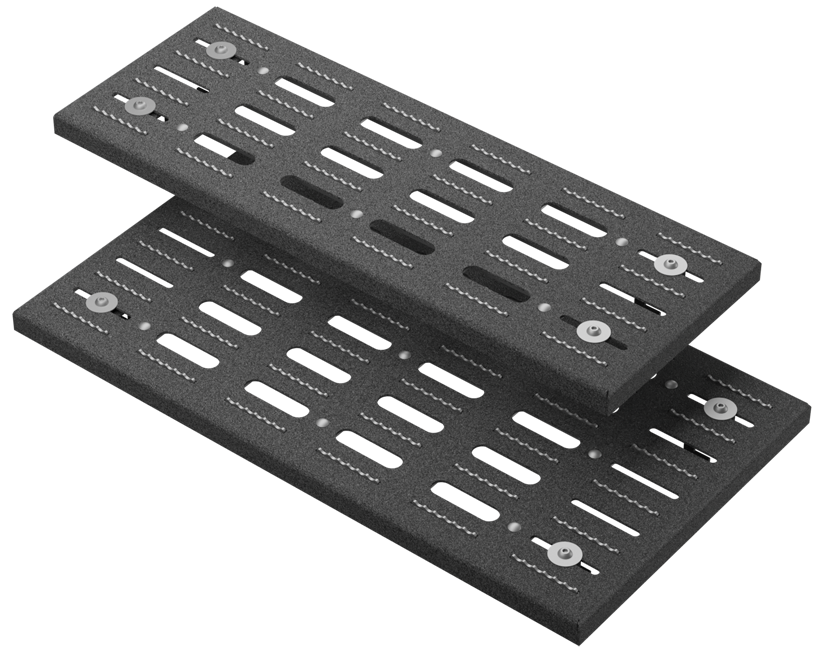

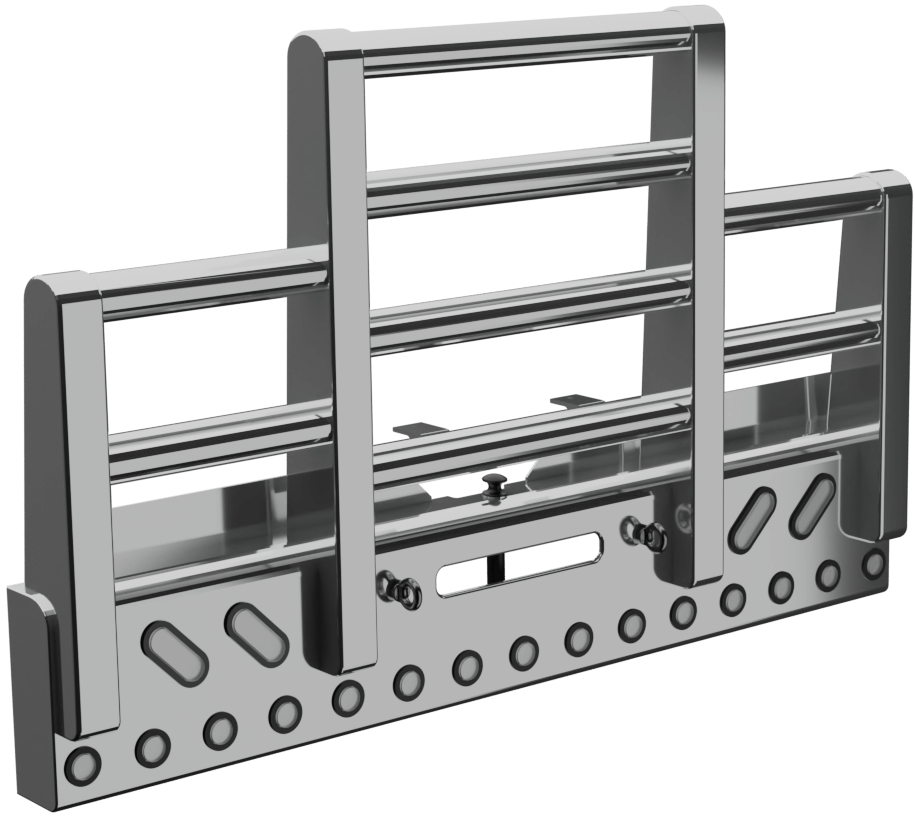

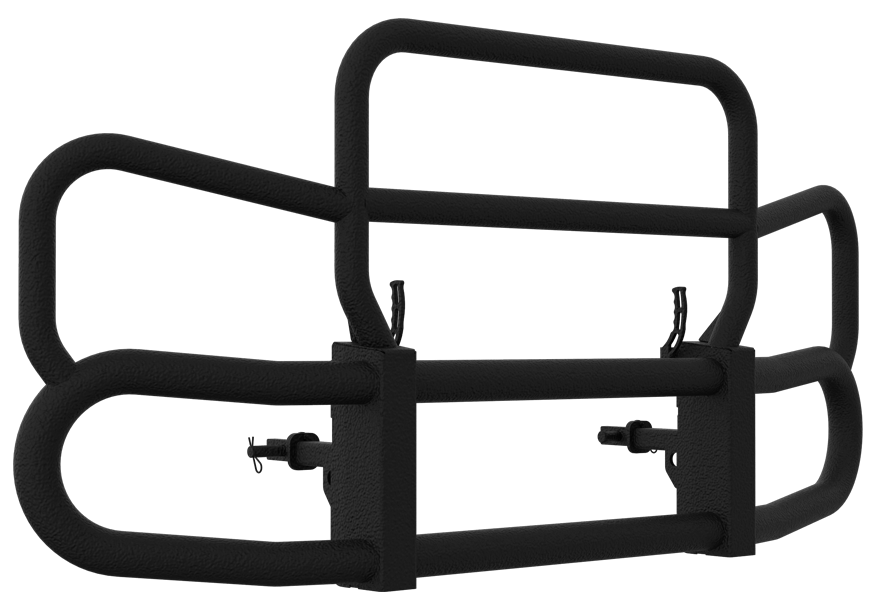

Whether you drive a pickup, a semi, or something in between, it is always a smart idea to install front-end protection on your truck. There is no harm in doing so, and it can potentially save you a great deal of money and frustration in the future. Read More

February 20, 2023

A large diesel truck hauling a huge rectangular storage trailer with several sets of wheels, counting to 18, comes to mind at the mention of a semi-truck. When something so big comes with the name, it is hard not to wonder why the trucks are counted as only half. The “semi” term in semi-truck refers to the trailer portion. This portion is technically only half-sized according to when the vehicle design first originated in France in 1769. This was when Nicolas J. Cugnot developed his experimental artillery tractor. Read More